Manual Cable Cutting Tool 6-70mm²

- 9.90€

- 9.90€

- Unit price

- per

Manual Cable Cutter for 6–70 mm² Cables | Durable Steel Handles

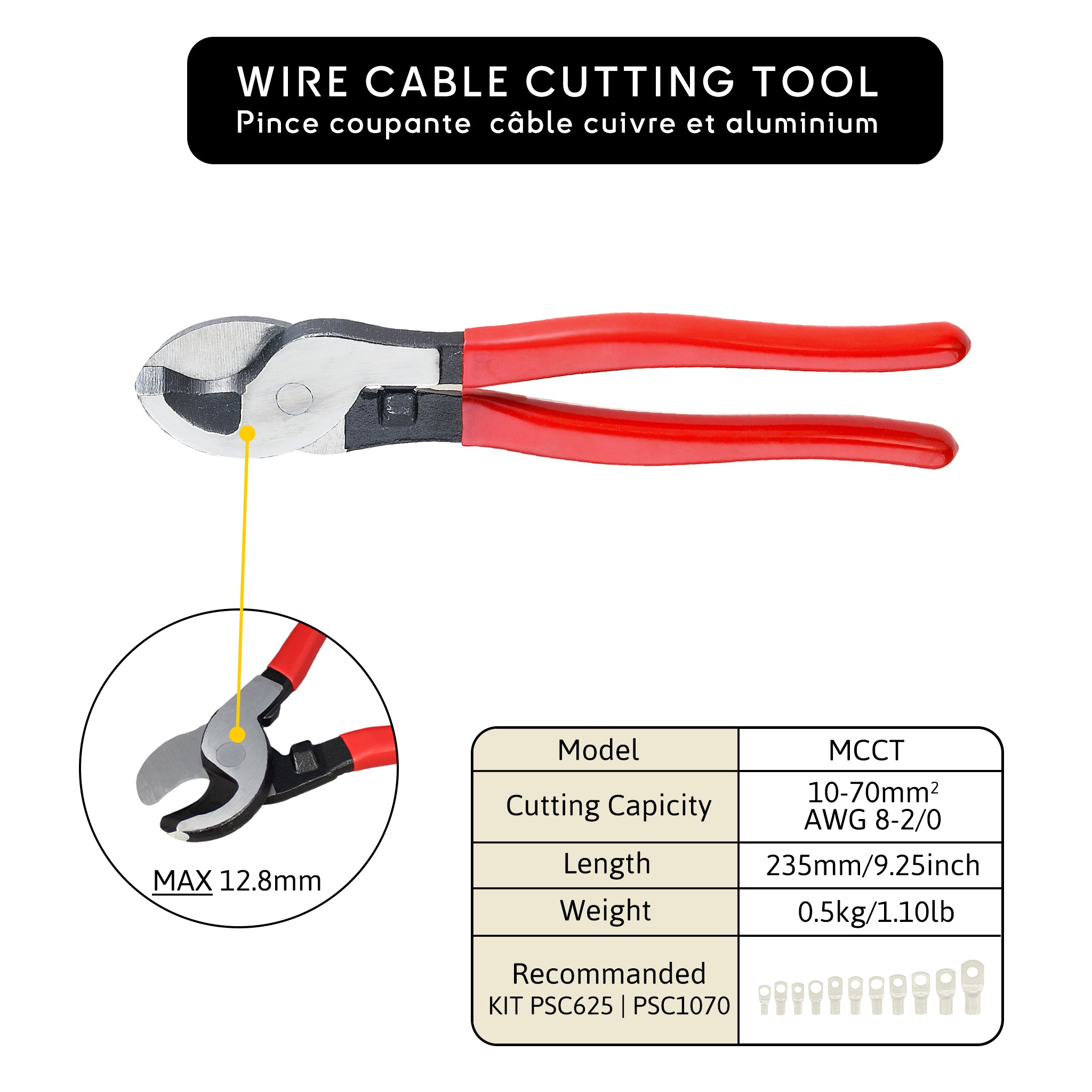

🔧 Precise and Consistent Cutting: The MCCT manual cable cutter is designed for clean cuts on copper and aluminium cables up to 70 mm² (AWG 8 to 2/0). Its optimized blade profile and 12.8 mm maximum opening ensure a neat cut without excessive strand deformation – ideal for preparing cable ends for crimping (ring terminals, tubular lugs).

🏋🏻♀️ Built to Last: Heavy-duty steel handles for maximum rigidity, precision pivot to reduce play, and integrated stop to prevent overloading and preserve blade sharpness. Balanced force-to-efficiency ratio reduces operator fatigue on large cross-sections while maintaining fine cutting control.

🌊 Made for Onboard and Workshop Use: Recommended for Boat electrical work (outboard engine feeds, switch panels, converters, busbars), automotive (tow bars, winches, audio), and industrial environments (control cabinets, maintenance). The MCCT handles common flexible multi-strand cables (H07RN-F, battery cables, inverter feeds, solar cables) and marine-grade aluminium where reduced cable weight is required.

🧰 Best Cutting Practices:

- Ensure the cable is off power and accessible (clean outer jacket, adequate bend radius).

- Position the cable deep into the blade groove to prevent strand slippage.

- Close progressively until the cut is complete, avoiding twisting the tool.

- Deburr if necessary for optimal crimping (clean surface, strands aligned).

🚫 Usage Limitations: Not intended for steel/stainless steel cables, wire ropes, rigid armored cables, chains, or bolts. Do not use on live conductors. For ACSR or rigging wire, use a dedicated cutter.

⚠️ Safety: Sharp blades – for adults and trained professionals only. Wear gloves and safety glasses. Keep out of reach of children.

🧼 Quick Maintenance: Wipe clean after use, especially in saline environments, and apply a light coat of oil to the pivot and blade. Store in a dry place (toolbox) to maintain smooth operation.

⚙️ Specifications:

- Model: MCCT

- Maximum blade opening: 12.8 mm

- Cutting range: Copper & aluminium up to 70 mm² (AWG 8 → 2/0)

- Weight: 0.5 kg

- Length: 235 mm

🔎 Compatibility & Common Use Cases:

- Battery & starter: clean cuts on 25–70 mm² cables for starters, battery switches, VSRs.

- Power distribution: preparing cables for busbars, ANL/MEGA fuse holders, thermal breakers.

- Power electronics: converters/chargers, light electric propulsion, windlasses.

- Onboard repairs: quick interventions in engine rooms or battery lockers with a clean cut before crimping.

🧩 Compatible Cable Types:

- Flexible multi-strand copper (battery, H07RN-F, welding cable) up to 70 mm².

- Marine-grade aluminium up to 70 mm² (check lug compatibility).

- Indicative AWG sizes: 8, 6, 4, 2, 1/0, 2/0 (rated for 2/0 max).

🛠️ Why a dedicated cutter instead of a saw/knife?

A dedicated shear preserves the strand geometry (better contact surface) and avoids crushing or burrs that complicate crimping. Result: lower contact resistance, reduced heating, and improved reliability in marine environments.

📦 Shipping & Use: Ships from France. For best results, practice on a scrap piece of the same section before your first live installation.

💡 Pro tip: For large cross-sections (50–70 mm²), mark the cut line, align the blade perfectly perpendicular, and use a small tape wrap around the strands before cutting – you’ll get a perfectly round, clean end for 360° crimping.

🔗 Order your MCCT for clean, fast, and repeatable cuts – the foundation of a reliable 12/24/48 V crimp connection.

Discover tips, tricks, and detailed instructions on using our product in our dedicated blog post. Learn about setup, operation, and optimization to get the most out of your purchase.

Link to the blog

Our Recommendations

- 34.50€

- 34.50€

- Unit price

- per

- 22.00€

- 22.00€

- Unit price

- per

- 17.50€

- 17.50€

- Unit price

- per

- 19.00€

- 19.00€

- Unit price

- per

- 32.00€

- 32.00€

- Unit price

- per

- Choosing a selection results in a full page refresh.